Concrete wheel stops vs rubber wheel stops: which one is better?

While motorists should, at all times, be wary of his/her surroundings, they should be extra careful when parking their motor vehicles due to the high probability of hitting any curb, vehicle, or bollard.

Due to such dangers, wheel stops are an excellent invention. Wheel stops are an amazing invention by transportation engineers, which act as a barricade between motor vehicles and other obstacles such as mirrors and pavements.

However, wheel stops are made from different parking kerb materials, such as concrete and rubber, the two most popular materials.

If you’d like to learn about different types of car stops, feel free to check out here: Discover different types of car stops!

Let’s delve into the specifications of both materials and identify which is better.

What makes rubber parking kerbs special?

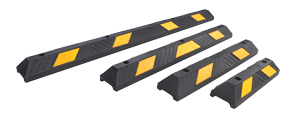

From rubber wheels to speed bumps, rubber products are widespread. Even wheel stops are made from recycled rubber tires, which have many advantages.

Here are some facts which make them popular.

- Rubber wheel stops can remain stable even on uneven surfaces like rough roads, gravel, or concrete. It can adapt to any surface and will fixate on its position without budging.

- Rubber wheel stops are non-abrasive and won’t cause any wear and tear to motor vehicles. On the other hand, the vulcanized rubber is strong enough to withstand multiple collision impacts from cars.

- Since it’s made from recycled rubber tyres, they are 100% environmentally friendly. Not only does it promote pedestrian safety, but it also supports the environment.

- Using only bolts and a hammer, you can install them within minutes. Also, they are extremely lightweight, making them easier to carry.

- Rubber wheel stops have reflective colours, making spotting them in dark underground passages easier. Many of them have bright paints with reflectors that increase their visibility. You can also get them in blue, perfect for handicapped individuals since blue is one colour they can observe.

All about concrete wheel stops

Precast concrete and asphalt are the prominent and sturdiest materials to create wheel stops.

Here are some of the facts about concrete wheel stops:

- They are the heaviest and can go up to 500 lbs. Therefore, it can take up to 4-5 people to carry and install them. On the other hand, their heavyweight makes them stable on the surface. Even after heavy vehicles collide, these wheel stops remain in place.

- Some manufacturers even use reinforced steel rebars in their concrete slabs. Therefore, it makes them more durable and less exposed to outside elements such as rain and sunlight.

- Once you install them, you can forget about their maintenance. They only require repainting, and that too, after several years. Plus, you can paint them in any reflective colour, including yellow, black, blue, and white.

- Concrete is permeable, and the structure is porous, making them susceptible to rain and sunlight. Therefore, if they are exposed longer, you may expect concrete to crack and chip away after some time.

Rubber vs concrete: which one is better?

Both materials have numerous applications in the construction, chemical, and traffic-calming industries. Since both have different shapes and structures, it’s difficult to decide which is more effective.

Nevertheless, let’s reach a conclusion after comparing the facts of both materials.

- Starting with strength, concrete definitely wins here.

However, there are chances that concrete can crack after repetitive impacts.

On the other hand, rubber wheel stops are lightweight, but they won’t tear at the vehicle’s collisions. Emergency vehicles such as fire trucks, ambulances, and buses will not damage these wheel stops.

- Secondly, concrete slabs are quite high, leading to substantial damage to vehicles. They may even damage cars’ bumpers, increasing your repair bills.

In contrast, rubber wheel stops only come in contact with a car wheel, causing no damage to your vehicle.

- Concrete is quite cheap compared to rubber wheel stops. However, you may need to repaint and maintain concrete slabs.

On the other hand, rubber wheel stops can have a permanent colour after moulding.

- Considering its weight, concrete takes time and can be difficult to install. On the other hand, rubber wheel stops have pre-drilled bolted holes, making installation quick.

- If concrete is used indoors, it’ll last longer because the wheel stops will not be exposed to outdoor elements.

On the other hand, wheel stops may work well outside in a parking lot or a designated parking space. Hence, a concrete wheel stop is good for you if you want to create a safe driveway. Rubber wheel stops will be more suitable for a roadway.

With the abovementioned differences, both materials are suitable for their respective applications. Despite being expensive, rubber wheel stops are more durable, versatile, and safe.

Alternative materials for wheel stops

Many people consider concrete and rubber the only material for traffic control devices such as wheel stops, wheel chocks, speed humps, and ramps. Not to be mistaken, several other materials can create effective wheel stops.

Some of them include the following:

- Plastic

- Metal

- Wood

Known to have numerous applications across all industries, plastic is effective. Despite being much lighter than concrete, plastic is undoubtedly quite strong. Polyurethane (PU) and polypropylene (PP) are high-density plastics that can make wheel stops.

Wheel stops can become indestructible with this material and can even prevent a trailer or truck wheel from hitting any obstacle. As a result, they are suitable in a loading dock where heavy-duty vehicles such as trailers and forklifts are parked.

Metal is another strong sealing barricade for parking lots. If it’s galvanised, you can prevent rust by powder coating them. However, their strong structure may damage vehicles, but they are equally effective in stopping vehicles.

Despite being useful in the construction and paper industry, wood and timber logs can be great wheel stops. However, they exist in their natural colour and may not be visible at night or in terrible weather conditions like fog and rainy weather.

Alternative tools for wheel stops

Wheel stops can prevent fatal traffic accidents. However, they are not the only tools.

Here are some other common measures to restrict parking fatalities:

- Using bollards, speed limit signs, and stop signs can help discourage motorists. Also, if police enforcement acts strictly with speeding vehicles and issues fines, parking accidents can be prevented.

- Installation of parking permits and strict regulations can help people remain vigilant while parking.

- Using signs of parking rules and bollards can prevent drivers from driving on a walkway or crosswalk.

Conclusion

So far, you must be aware that the world has changed, and the contest between rubber and concrete is less relevant now due to the availability of so many cost-effective tools. Therefore, the best parking kerb will depend upon your situation.

Usually, property owners will prefer concrete parking kerbs since they can last long indoors. Rubber can be a good choice if you’re not a property owner and want to install one on commercial properties.

Are you wondering where you can get high-quality wheel stops? Contact us on Sino Concept, where we manufacture reflective vulcanized rubber wheel stops.

Not only that, but you can also look for other traffic calming measures, such as speed bumps and ramps, on our website. Visit our website now to confirm your order.

To learn more, we advise you to refer to the following pages: