Discover different parking kerb materials!

Despite the traffic control and traffic organization parking brings, parking always has some mishaps and damage. Be it broken bumper, car collisions, or ramming onto pavements, parked cars can suffer great damage.

Fortunately, the traffic engineering department has developed a suitable safety measure, i.e., parking kerbs – an obstruction between vehicles and the pavement curbs.

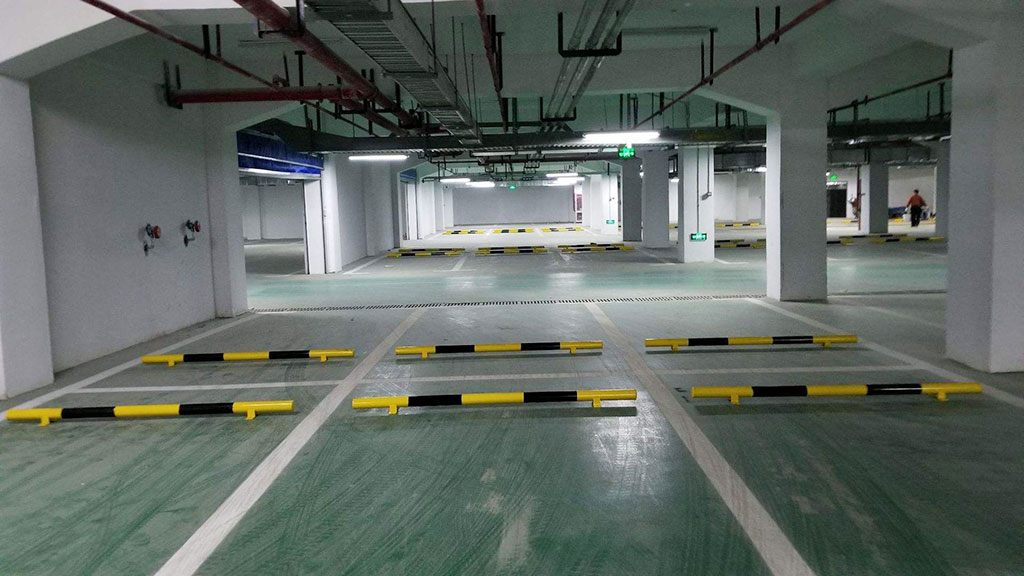

Having many names, including wheel stops, parking blocks, and wheel chocks, a parking kerb increases safety in parking lots.

From residential parking spots to commercial parking zones, you must have seen these blocks acting as a barrier between the tires and the pavement. Parking kerbs, on the other hand, are made from numerous materials.

In this blog, you’ll learn about the different types of car stops material and their lesser-known facts.

Pros and cons of rubber parking kerbs!

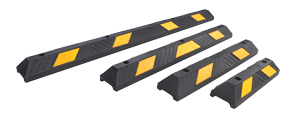

Who doesn’t like to have a parking kerb that lives up to expectations and doesn’t wear out soon? If you are looking for one, rubber is the material you should go for. Rubber parking kerbs have been creating headlines recently due to their exciting advantages.

Let’s take a look at some of them:

- Have you ever encountered a parking stop that can stay sturdy on uneven, rough concrete, gravel, wood, or asphalt surfaces? Rubber is extremely flexible and will stay still in its position.

Rubber wheel stops will work best if you want to install them in a rugged parking spot or create reserved parking in your residence or office.

- Most rubbers go through vulcanization – a process that increases the strength of rubber and makes them difficult to deform. Even if you install them in HGV parking lanes, the rubber will not crack due to the vehicle’s constant impact.

A rubber block will promise a long-lasting solution if you have 4WD motor cars and want to create a parking spot in your concrete driveway.

- Rubber parking kerbs can be of great value if you advocate for a cleaner environment and want to create a driveway that supports your values. Made from 100% recycled rubber tires, rubber wheel stops are environmentally friendly and complement your driveways by creating an appealing look.

- Why waste money when you can install it yourself? You heard that right. Being naturally lightweight and simple to install, pick up your drilling machine, hammer, and bolts to create parking spaces.

Despite the prosperity, rubber wheel stops have shortcomings, such as high cost and colour fading. Due to the involvement of so many processes, the cost of rubber wheel stops is high, making them unaffordable for some people.

While rubber wheel stops have reflective strips, crossings, and markings, their paint can fade after several years. However, if the paint is moulded with rubber, the colour is permanent.

Concrete wheel stops vs rubber wheel stops: which one is better?

You have seen the lightweight wheel stops. Let’s examine the heaviest type, which incorporates the use of concrete. Despite having numerous construction applications, concrete slabs act as effective wheel stops.

However, it’s not easy to select between rubber and concrete.

Let’s look at some differences and identify the better type:

- In terms of strength, concrete wheel stops have reinforced steel bars, making them heavy and quite stable on the surface. However, the high strength may cause destructive damage to vehicles if they collide with concrete stops.

On the other hand, rubber wheel stops are less heavy but don’t cause considerable damage to motor vehicles.

- While concrete wheel stops seem long-lasting, this case only applies if installed indoors. Due to exposure to outside elements, concrete wheel stops cannot thrive well outdoors.

They have permeable structures and porous openings, causing cracks and breaking after a while. On the other hand, rubber is weather-friendly and can thrive well outside.

- You can paint any colour on concrete. Be it blue for handicapped parking or yellow or black for usual vehicle parking, you can get concrete wheel stops in any combo.

However, the colour may fade away after some time, requiring maintenance. In contrast, rubber wheel stops have limited colour options, but they have long-lasting paint due to moulding.

Nonetheless, rubber is better since it can withstand equal vehicle collisions and will not crack due to weather conditions.

However, if your home has garages, an indoor concrete wheel stop can work for you since it’ll not get damaged indoors.

Advantages and disadvantages of the steel wheel stops!

Having discussed the two prominent materials, let’s look at steel as a material for wheel stops.

While it’s uncommon and fewer companies offer it, steel wheel stops have some overwhelming pros, making them suitable parking areas for loading zones, visitor parking, supermarkets, and schools.

Some of them include the following:

- The steel is galvanised with a hot mix, making it stronger and rust-free. Hence, it prevents your car’s tires from moving forward in a parking lot.

- You’ve got it wrong if you think that steel wheel stops will have a shiny rusty colour. They can become extremely visible after yellow powder coating. Yellow, in general, is bright and reflective, enabling drivers to spot them easily.

- Pedestrians feel safe walking on city sidewalks near parking facilities due to the presence of steel wheel stops. If a driver is distracted during parking, these wheel stops can protect curbs, walls, and mirrors by stopping them.

If they are absent, you may drive into the structures, leading to heavy fines, violations, and hazards.

Besides being less common, steel wheel stops have disadvantages, such as fading paint and heavyweight. Despite being simple to install, steel wheel stops are difficult to carry due to their strength and heaviness.

Also, their paint is not durable and may wear out after constant vehicle collisions.

Five facts to know about wooden wheel stops!

Even in street furniture, wood is pivotal in reducing accidents. However, wooden wheel stops are a very rare material to create parking zones.

Let’s look at some of the lesser-known facts about wooden wheel stops:

- Mostly, it’s difficult to paint logs and wood since they exist in natural colour. Therefore, they may not be visible in dark surroundings, leading to fatal accidents.

- Some wooden wheel stops may also break or crack upon constant collision of vehicles.

- Despite being aesthetic, they are 100% environmentally friendly and can increase fresh air in the atmosphere.

- Their installation process is similar to installing concrete and rubber wheel stops, which use hammers and bolts.

- They can thrive well for around 20-25 years, making them a suitable long-term option.

Five truths about plastic wheel stops!

So far, you’ve got to know about the prominent material for making wheel stops. However, there is still one major material left, i.e., plastic. Be it the chair you’re sitting on or the glasses you’re wearing to read this blog, it’s everywhere.

Even for traffic control devices, plastic is quite a stable and strong material, creating long-lasting wheel stops.

Some of its exciting facts are as follows:

- Plastic wheel stops are incredibly lightweight, around 9-11 kgs. You can carry and install it easily within ten minutes.

- While being 20% the weight of concrete, they can withstand a load rating of 40,000 lbs. Like polyurethane (PU), some plastics are strong enough to endure collisions with heavy trucks in a loading zone.

- Since wheel stops are made of recycled plastic, it’s also environmentally friendly because if it weren’t for wheel stops, plastic would pollute rivers.

- Ranging from blue colour for disabled parking to yellow colour for standard parking regulations, you can have plastic wheel stops in any colour. If the colour is moulded, the chances are that the paint will be permanent.

- Some plastics are UV friendly, making them durable enough to avoid cracking or chipping away due to weather conditions.

Alternative parking safety tools

Besides installing wheel stops, some traffic authorities like the department of transportation, the federal highway, and the department of public works have some measures in place.

Some of the inspections and traffic enforcement tools to increase parking safety includes:

- Issuing parking permits enables people to follow parking rules and be vigilant while parking their cars or motorcycles.

- Some traffic zones have parking tickets and fines to discourage illegal parking in lots.

- Install parking signs on walkways and curbs to instruct drivers about the parking distance.

- Using curb ramps and steel bollards to increase the visibility of parking lot lanes.

Conclusion

Indeed, choosing a suitable material for wheel stops is essential because each material has different effects for various vehicles. For example, heavy-duty vehicles such as buses or trailers may damage concrete or low-strength plastic kerbs.

Furthermore, you must consider pedestrians and handicapped people before you choose the colour for your wheel stops.

Hence, choosing a high-quality provider must be your top consideration if you’re considering installing wheel stops on your driveways, private property, offices, or factories.

We provide high-quality rubber wheel stops for garage parking, city streets, pavements, and property owners at Sino Concept. You can find other traffic measures on our website, such as speed bumps and ramps.

Reach out to us to get a quotation for expanding your parking options.

To learn more, we advise you to refer to the following pages: