Our PRODUCTION PROCESS

At Sino Concept, we manage the entire production cycle in-house, from product design and raw material selection to manufacturing and packing.

We specialise in plastic-rubber composite, rubber, plastic, and steel products, with strict quality control at every stage.

We design and own all our moulds and carefully select our raw materials to ensure consistent quality and full control over every step.

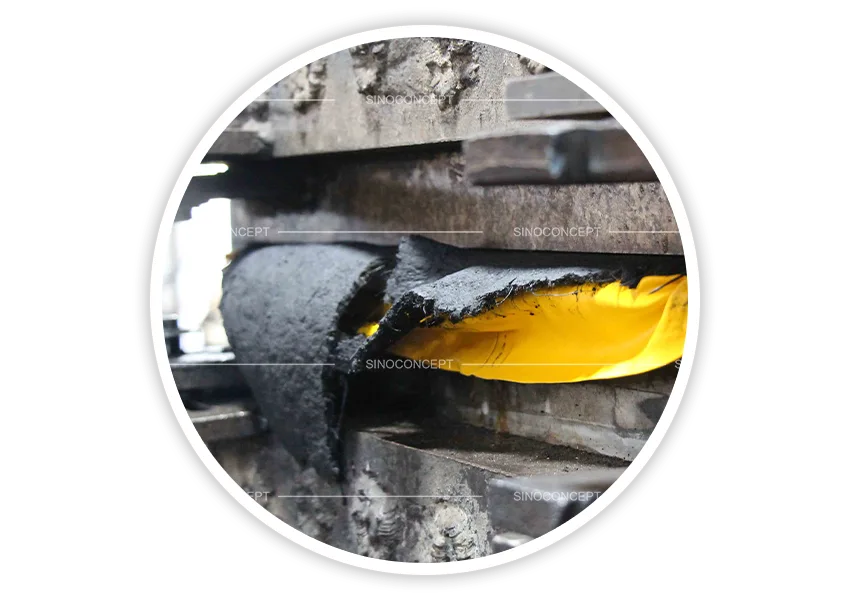

Rubber & Plastic-Rubber Composite

We manufacture all rubber and plastic-rubber composite products in-house, ensuring full control over each step of the process.

Processes:

- Vulcanisation (rubber)

- Compression moulding (plastic-rubber composite)

Materials:

- Rubber: 90% recycled + 10% virgin rubber

- Plastic-rubber composite: Mix of recycled plastic and rubber

Products:

Speed bumps, wheel stops, cable protectors, speed cushions

Steel Manufacturing

Our steel products are entirely manufactured in-house, from raw tube processing to surface finishing.

Processes:

Welding, stamping, bending, hot-dip galvanising, powder coating

Materials:

Steel tubes, ductile iron

Products:

Bike racks, crowd control barriers, street barriers, bollards, and street furniture

Plastic Manufacturing

We also handle all plastic production in-house, allowing seamless coordination with our rubber and steel divisions.

Processes:

Injection moulding, blow moulding

Materials:

PP, PE, PVC, EVA, PU, including recycled options

Products:

Traffic cones, drop-over cable covers, roadwork beacons, plastic sandbags

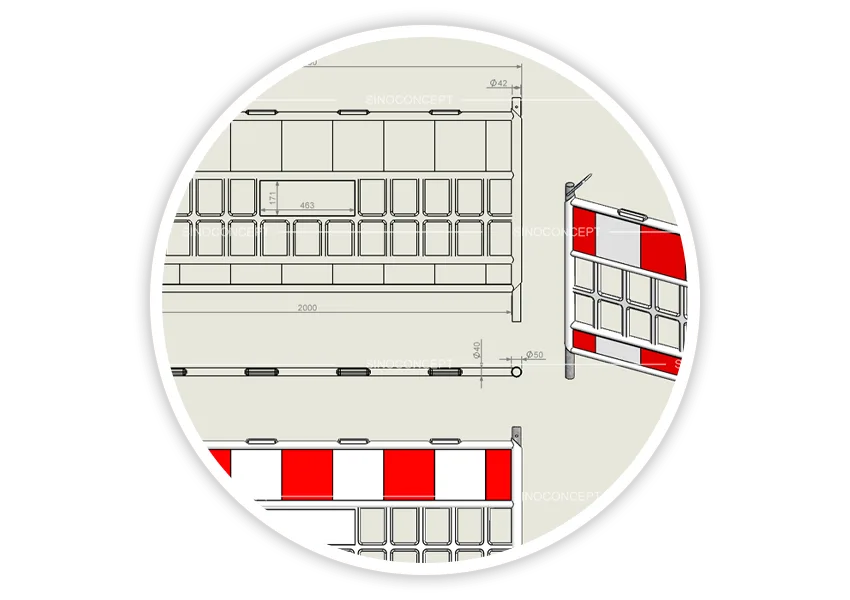

Custom Manufacturing

Looking for a custom product?

At Sino Concept, we offer tailor-made solutions developed according to your exact specifications, whether it’s a small adjustment or a completely new design.

Our in-house design team works closely with our production departments to ensure your product is not only technically feasible but also optimised for industrial production.

We focus on functionality, visual consistency, and compliance with international safety standards, to deliver practical, reliable, and well-designed products that match your needs.

From the first sketch to the finished item, we manage the entire process with efficiency, precision, and attention to detail.

Quality at Every Step

From raw material selection to final inspection, we apply rigorous quality control procedures to ensure that all products meet technical requirements and regulatory standards.

Got a project in mind? Let’s make it happen, contact us today!